Features

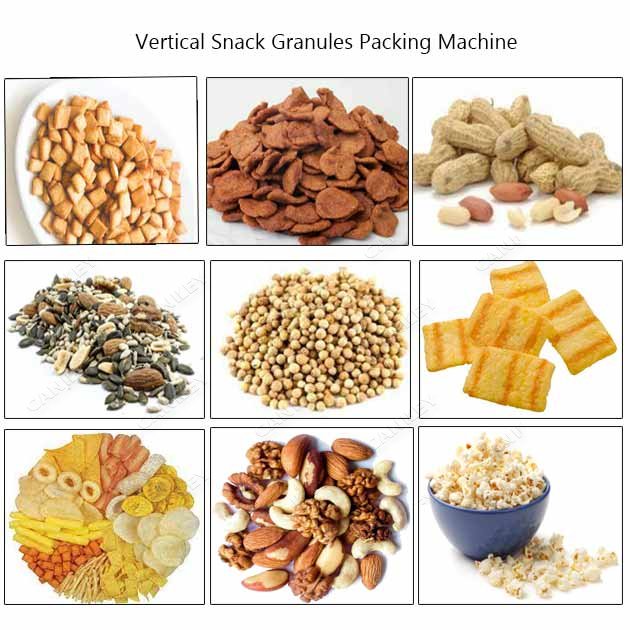

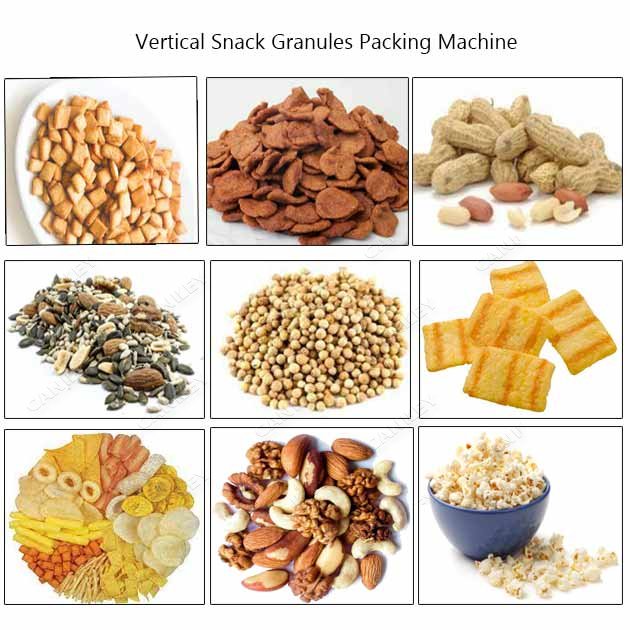

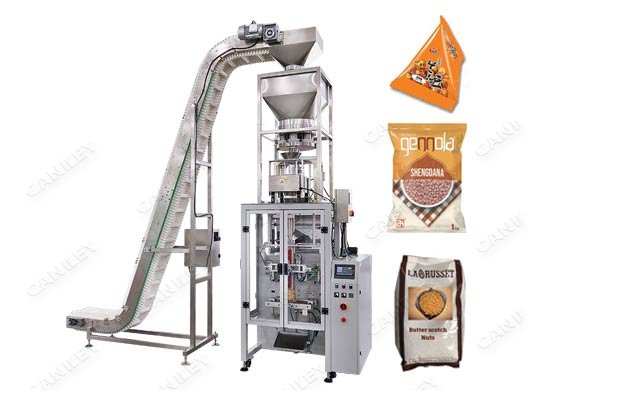

Kuli kuli packing machine is a kind of vertical granule packing machine, which can pack various snacks like kuli kuli, chin chin, dal, snack pellets, seeds etc. and the package is injected into the bag, and the horizontal sealing mechanism is colored according to the color.

During the packaging process of the kulli kuli packing machine, the material is fed by the material stretching and feeding device, and the plastic film is formed into a cylindrical shape through the film cylinder, and the side surface is sealed by the heat longitudinal sealing device, and the package is injected into the bag, and the horizontal sealing mechanism is colored according to the color.

The standard photodetection device cuts the package length and position.The vertical granule packing machine is suitable for packaging of granulated strips, short strips and powder strips such as puffed food, shrimp strips, peanuts, popcorn, oatmeal, melon seeds, jelly, white sugar, salt, dal, cashew nuts, chin chin,etc

During the packaging process of the kulli kuli packing machine, the material is fed by the material stretching and feeding device, and the plastic film is formed into a cylindrical shape through the film cylinder, and the side surface is sealed by the heat longitudinal sealing device, and the package is injected into the bag, and the horizontal sealing mechanism is colored according to the color.

The standard photodetection device cuts the package length and position.The vertical granule packing machine is suitable for packaging of granulated strips, short strips and powder strips such as puffed food, shrimp strips, peanuts, popcorn, oatmeal, melon seeds, jelly, white sugar, salt, dal, cashew nuts, chin chin,etc

Equipment features of the kuli kuli dal packing machine:

1. Product packaging, printing date is completed once. Save time and save costs;

2. Optimized structural design, disassembly, cleaning is more convenient;

3. Horizontal and vertical sealing temperature independent control, better adapt to various packaging materials;

4. According to the material conversion opening and closing mode metering device.

Technical Data

| Model | CK320 | CK350 | CK480 |

| Total Power | 220V/2.5kw | 220V/2.5kw | 220v/1.8KW |

| Capacity | 10-100ml | 40-200ml | 200-1000ml |

| Width of film | 80-280mm | 80-300mm | 180-420mm |

| Bags size | L:30-180mm w:30-130mm | L:30-280mm w:30-140mm | L:40-300mm w:80-200mm |

| Machine size | 820*980*1680mm | 820*980*1980mm | 900*1100*2080 |

| weight | 300kg | 300kg | 450kg |

| Thickness of film | 0.03mm-0.07mm | 0.03mm-0.07mm | 0.04mm-0.08mm |

Get Price

Get Price

E-Mail

E-Mail Whats

Whats TOP

TOP