Features

The ginger juice beverage bottling filling line is a hot-filling machine integrating washing, filling, capping and labeling. It is suitable for various fruit juice and beverage filling production lines, such as: Blueberry juice filling production line, kiwi juice filling production line, pear juice filling production line, grape juice filling Filling production line, apple juice filling production line, orange juice filling production line etc. The output is 5000-18000 bottles/hour, which can be customized.

The ginger juice bottle filling line adopts the advanced micro-negative pressure gravity filling principle, which is fast, stable and accurate. It is equipped with a complete material return system, and can also realize independent air return during return, without contact with the material, reducing the secondary pollution of the material And oxidation.

Advantages of ginger juice filling plant:

The ginger juice bottle filling line adopts the advanced micro-negative pressure gravity filling principle, which is fast, stable and accurate. It is equipped with a complete material return system, and can also realize independent air return during return, without contact with the material, reducing the secondary pollution of the material And oxidation.

Advantages of ginger juice filling plant:

♥ The three functions of rinsing, filling and sealing are combined in one body, the whole process is automated, and it is suitable for filling polyester bottles and plastic bottles.

♥The filling method adopts a new type of micro-negative pressure filling, which makes the filling speed faster and more stable. Compared with the machine of the same specification, the output of this machine is higher and the benefit is greater.

♥The advanced OMRON programmable controller (PLC) is used to control the automatic operation of the machine, and the bottle is fed with a new air duct, which is fast and without bottle damage.

♥The bottle transfer between each mechanism adopts the method of clamping the bottleneck. When changing the bottle shape, only a few change parts need to be replaced, which is extremely adaptable.

♥The photoelectricity detects the operating status of each component, with a high degree of automation and easy operation. It is the ideal equipment of choice for beverage manufacturers.

Maintenance of Ginger Juice Filling Line

Before and after production, the juice filling machine should be cleaned and maintained thoroughly and the fasteners of all parts should be checked. If there is any looseness, it should be tightened and repaired.

Check that the meshing surface of the transmission gear is abnormal and should be repaired, and then greased.

Every year at the end of seasonal production or when production is temporarily stopped, a thorough repair and maintenance should be carried out, and worn parts should be replaced in time to ensure normal production next time.

Note:

1. When cleaning the liquid juice filling machine, do not spill water into the rotating and electrical parts.

2. Bottles and caps of various specifications must comply with the relevant regulations in the technical parameters. Any bottles and caps that do not meet the regulations are strictly prohibited to use to avoid mechanical failure.

3. The transmission stations should be accurately and opposite each other to avoid bottle jams caused by misalignment.

4. Frequently check the lubrication parts to ensure sufficient lubrication

The juice beverage equipment adopts the advanced micro-negative pressure gravity filling principle, which is fast, stable and accurate. It is equipped with a complete material return system, and can also realize independent air return during return, without contact with the material, reducing the secondary pollution of the material And oxidation.

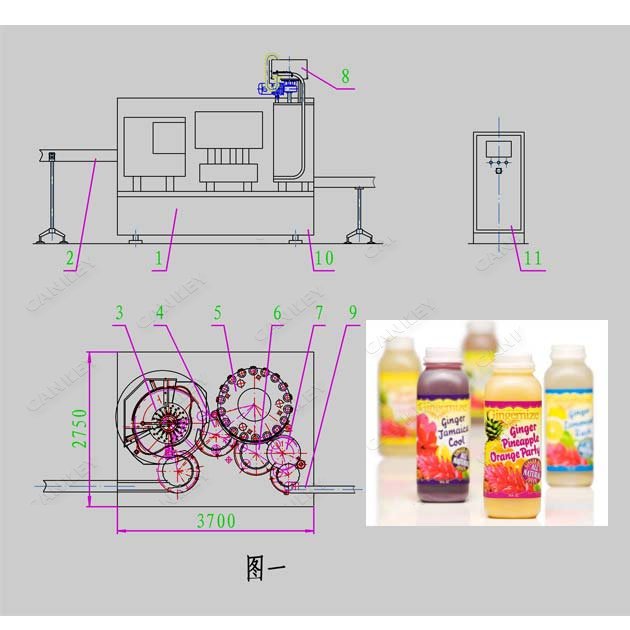

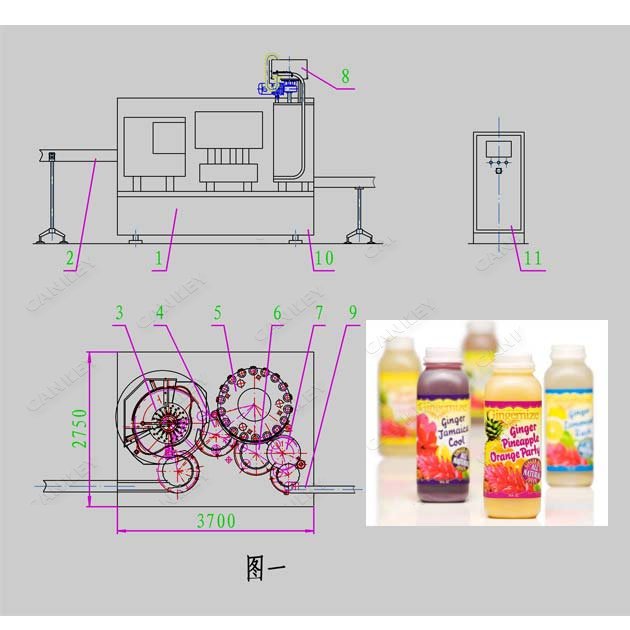

Technical Data

| Model | CK-GZ18/24/32TS |

| Filling Bottle | PET bottle,glass bottle |

| Measuring range | 350-2680ML |

| Bottle Size | ∅60-∅112mm,height180-330mm |

| Packing Speed | 5000-18000bottle/h |

| Filling valve number | 18-32 |

| Voltage | 380VAC/50HZ |

| Power | 2.5-7.5KW |

| Dimensions | 3400L×3000W×2700H |

| Weight | 4000KG-9000KG |

| Precision | ≤±1% |

Get Price

Get Price

E-Mail

E-Mail Whats

Whats TOP

TOP