Features

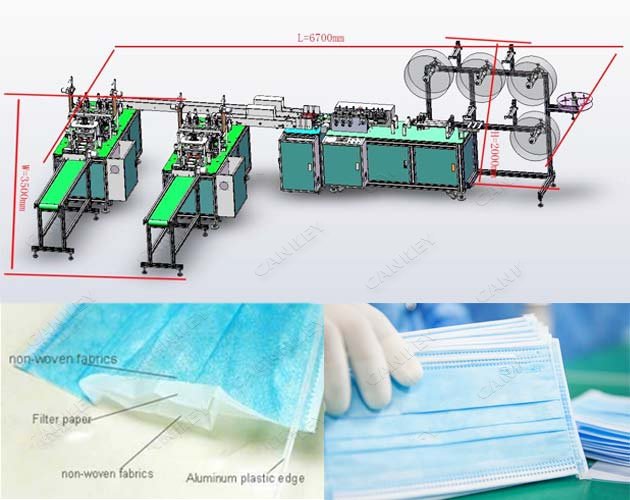

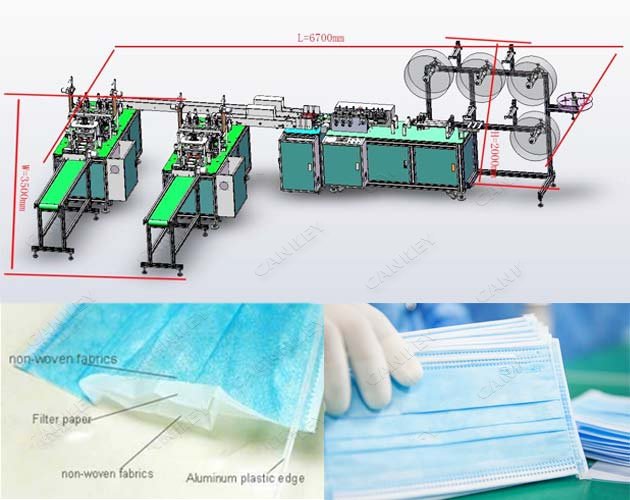

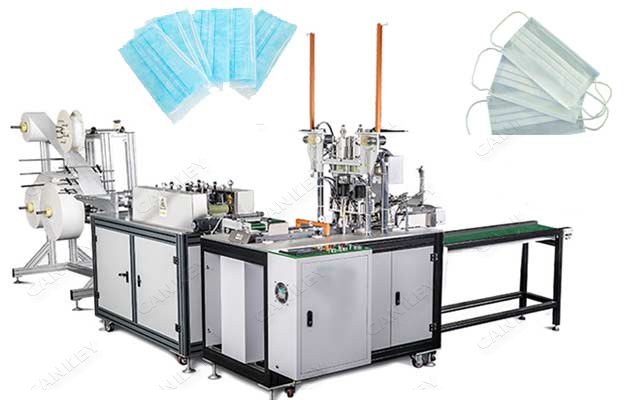

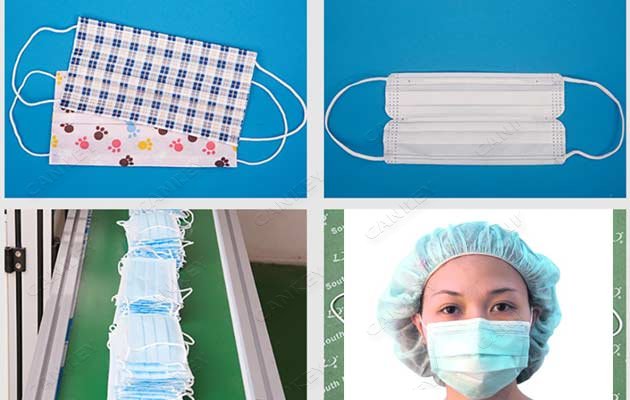

Fully automatic mask production machine is used for auto forming the face mask slice and add the earloop on the face masks from mask body production to ear band welding, nose line welding to final masks.Our automated masks making machine continuously assembles 3 layers of non-woven fabric.This process is fully automated, and the product parameters are easily controlled and monitored by the operating system.

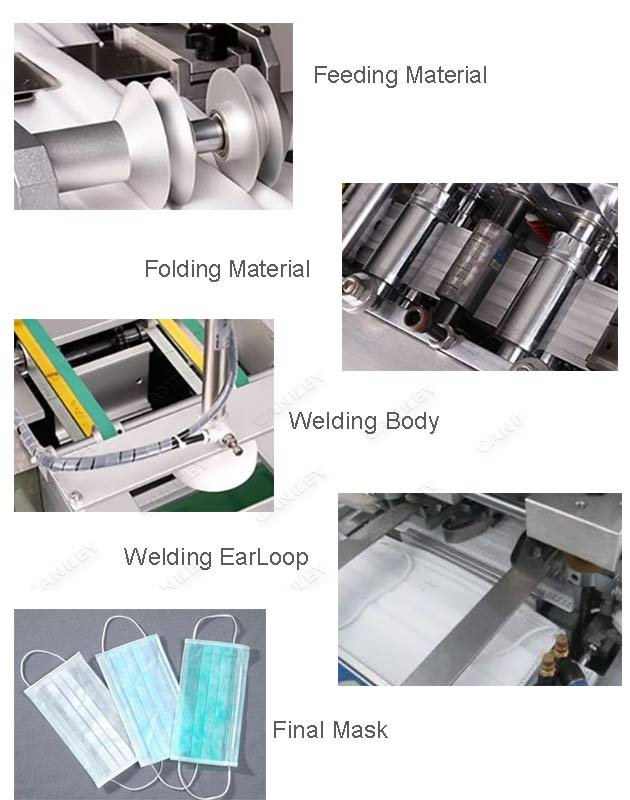

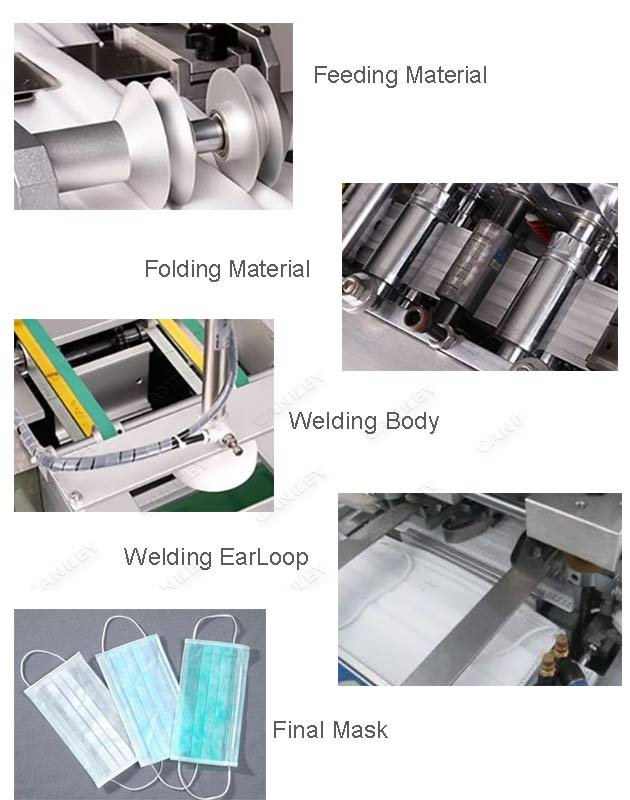

Work process of Mask Production Machine:

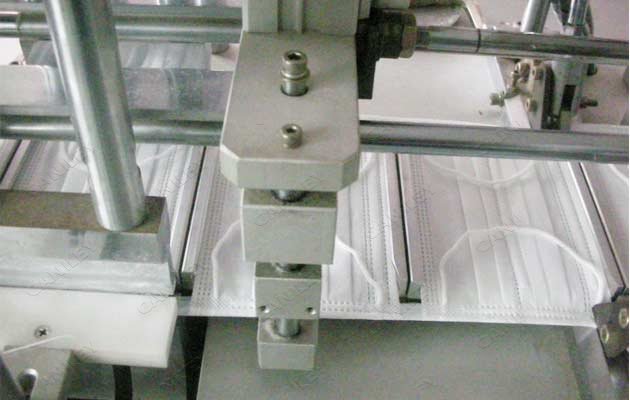

Mask body) manual feeding → automatic feeding of earbands → ultrasonic earband welding → non-woven sideband feeding and wrapping → ultrasonic sideband welding → sideband cutting → finished product output → counting → finished product stacking → conveyor belt delivery.

Advantages of Automatic Non-woven Masks Production Line:

1. Small size, fast speed, standardization, network communication capability, stronger function and high reliability

2. Titanium alloy ultrasonic special mold has longer service life and is not easy to be damaged.

3. Adopt imported cylinder, with large output and strong adaptability. It can work normally in high temperature and low temperature environment, and it is dustproof and waterproof.

4. Good motor quality, with good speed control characteristics, high efficiency, high speed control without heat generation, high precision position control, low noise.

Video:

Video:

Technical Data

| Model | CK-PK12 |

| Dimension | 6000(L)*5500(W)*1680(H) |

| Capacity | 90-110pc/min |

| Weight | 1600kg |

| Control | PLC |

| Voltage | 220V 50Hz |

| Power | 13kw |

Get Price

Get Price

E-Mail

E-Mail Whats

Whats TOP

TOP