Features

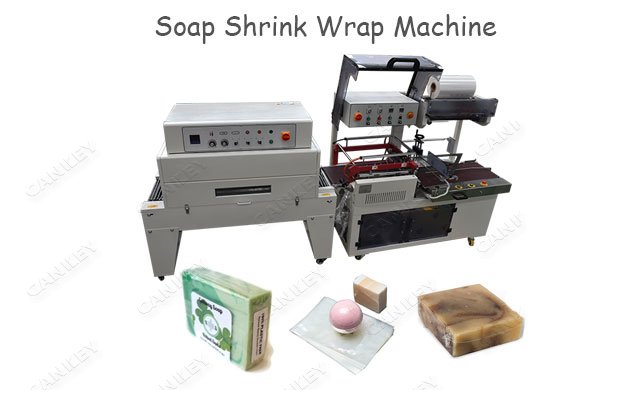

Full automatic shrink wrapping machine for yogurt box including side sealer and heat shrink tunnel which can feed products, seal and cut film and shrink film bag automatically. It is widely used in food, pharmaceutical,electrical appliances and other industry, like to pack milk bottles, yogurt box, beer box, tea box, water bottles, tableware, books etc.

Features of yogurt box shrink wrapping machine:

Sealing machine:

1. The bottle shrink sealing machine combines advanced foreign sealing technology, and continuous improvement and unique design and manufacture, sealing stability, the effect is particularly good. The company is located in:

2. The use of pneumatic pressure control, pressure, sealing effect is good. The company is located in:

3. The machine switches, controllers, pneumatic components and other major electrical components are made of high quality components, work stability, low failure rate. The company is located in:

4. Conveying motor The film-fed motors are all direct-coupled geared motor, strong driving force, continuous work.

Yogurt box shrink wrapping machine:

♥The machine is classic, absorbing advanced packaging technology, especially suitable for shrinking PP, POF and other environmentally friendly materials;

♥ The original temperature regulation function, leading peer, can completely solve the drawbacks of poor contraction of the bottom of the product;

♥ The delivery of solid roller (non-hollow tube), plus imported silicone tube, a long time without distortion;

♥ The only extension of the hot air duct industry (1200mm), to ensure that the perfect shrinking effect;

Working with PE shrink tunnel to pack the goods perfectly. The whole set of shrink wrapping machine producing process adopt the Germany advanced technics. And the main parts are imported from international famous companies,capability stable and using long-time.

Video:

Video:

Technical Data

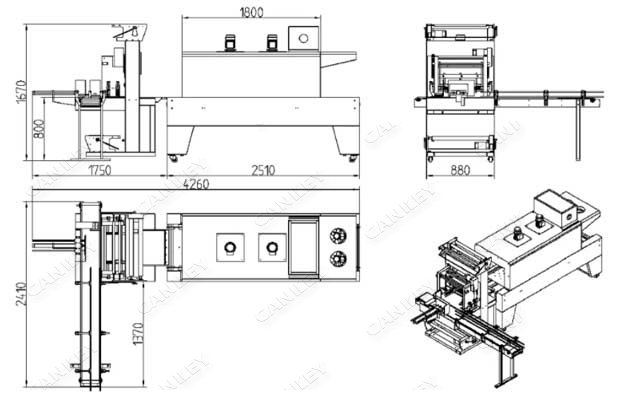

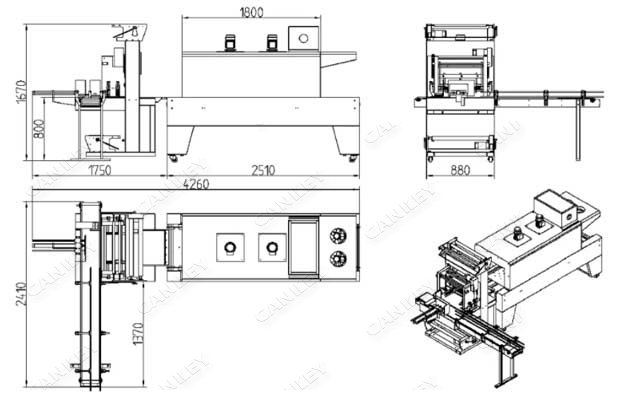

| Model | CKDQL5545G | CKDSC4525L |

| Max packing size(mm) | L+2H≤550, W+2H≤450,H<130 | W450×H250 |

| Max sealing size(mm) | L550×W450 | / |

| Power(KW) | 1.30 | 9 |

| Capacity | 0-24m/min | 0-16m/min |

| Voltage | 220V 50/60HZ | 380V 50/60HZ |

| Sealing temperature |

180℃—250℃ depends on thickness of film and environment temperature |

180℃—250℃ depends on thickness of film and environment temperature |

| Thickness of film(mm) | 0.015-0.10 | |

| Air pressure(Kg/cm2) ) | 5 | |

| Packing material | POF PVC | |

| Machine weight(㎏) | 320 | 220 |

| Machine size(㎜) | L1700×W900×H1400 | L1800×W703×H1260 |

Get Price

Get Price

E-Mail

E-Mail Whats

Whats TOP

TOP