Features

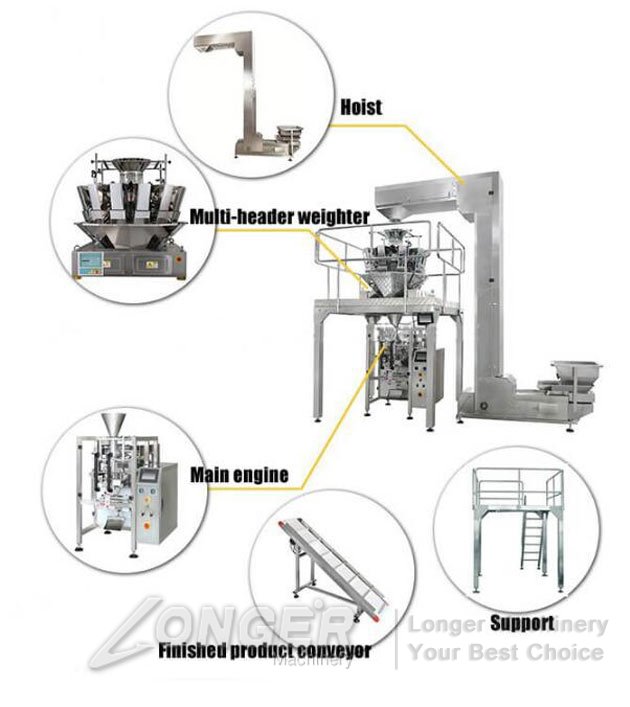

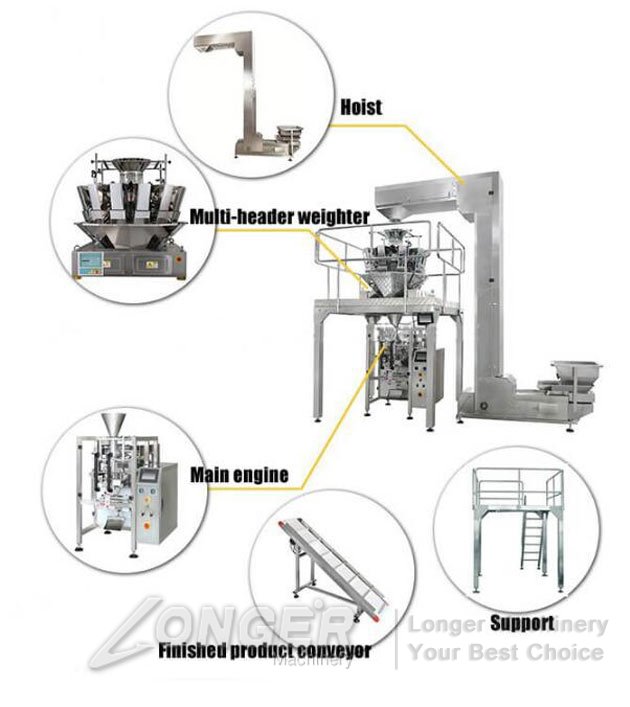

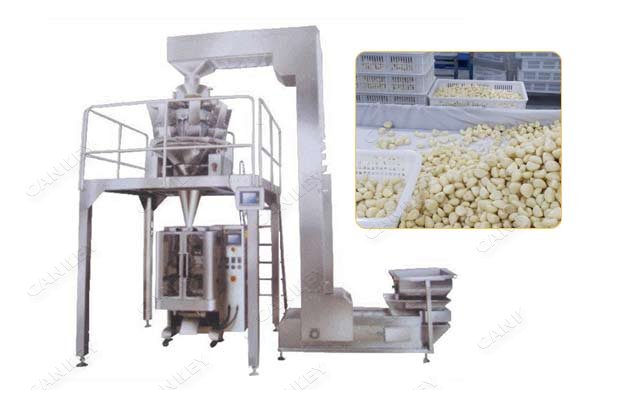

Automatic garlic packaging line can automatically complete the elevating, arranging, feeding, weighing, bag forming, filling and bag sewing of granuled products, like garlic, chips, cocoa beans, sugar, mung bean, peanut, etc. Equipped with touch screen, PLC controls all the functions of the machine, the garlic packaging line can be set all parematers on PLC control panel, which is convenient for workers.

The automatic garlic packaging line is suitable for many kinds of measuring equipments, and package different kinds of products: Puffed food, shrimp rolls, peanut, popcorn, potato chips, french fries, banana chips, kurkure, cornmeal, seed and sugar etc.

Technical characteristics:

1. It is controlled by a micro computer,with touching the screen,and the operation is simple .

2. PLC computer system, function is more stable , adjust it with any parameters ,and don’t need to stop machine.

3. It can stock ten dispose, simple to change variety.

4. Sever motor drawing film , position accurately.

5. Temperature independent control system ,precision degree get to±1°C.

6. Horizontal , vertical temperature control ,suitable for various of mix film, PE film packing material.

7. Packing type diversification, pillow sealing, standing type ,punching etc.

8. Bag–making, sealing, packing, printing date in one operation.

9. The machine can work with low noise.

Automatic garlic clove packing machine is with computer control and English-Chinese touch screen for easy operation without stopping the unit, and intelligent PID temperature controller for easy adjustment and good application to various laminated film and paper.

Video:

Automatic garlic clove packing machine is with computer control and English-Chinese touch screen for easy operation without stopping the unit, and intelligent PID temperature controller for easy adjustment and good application to various laminated film and paper.

Video:

Technical Data

| Electronic scale | Vertical packaging machine | ||

| Model | LGA10-1.6 | model | LGLK520 |

| Voltage | AC110/220V | Film width | MAX 520mm |

| Power frequency | 50/60HZ | Bag width | 90-250mm |

| Rated current | 8A | Bag length | 80-350twice pull film450mm |

| Power | 1.5KW | Packing speed | 10-70pc/min |

| Weighing number | 10 | Measuring range | 150-2000ml |

| Weighing rang | 3-6500g | membrane thickness | 0.04-0.10mm |

| Single weighing range | 10-1000g | Power Specifications | 3kw/220v 50-60hz |

| Weighing capacity | 1600ml | Machine size | 1430×1200×1700 |

| Maximum weighing speed | 70 pc/min | Machine quality | 650kg |

| Product preset number | 100 | Air consumption | 0.4cubic / minute 0.6mpa |

| Long form factor | 1050mm | Packaging material |

Bopp/cpp. Bopp/vmcpp bopp/pe. Pet/vmpet/pe pet/al/pe ny/pe pet/pet |

| Wide size | 900mm | ||

| High profile | 1330mm | ||

| Machine weight | 330kg | ||

| monitor | 7inch | ||

| Weighing accuracy | plus or minus 0.3-3 grams |

|

|

Get Price

Get Price

E-Mail

E-Mail Whats

Whats TOP

TOP