Features

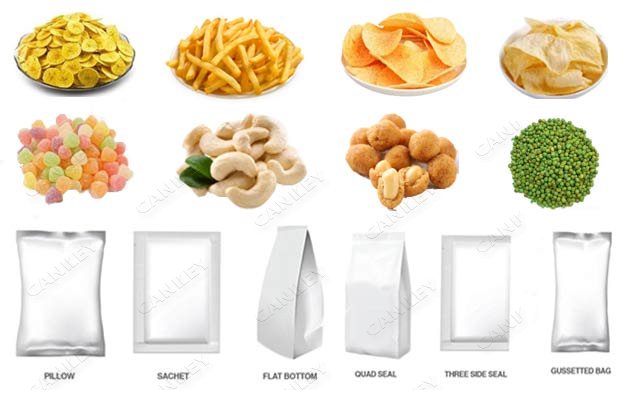

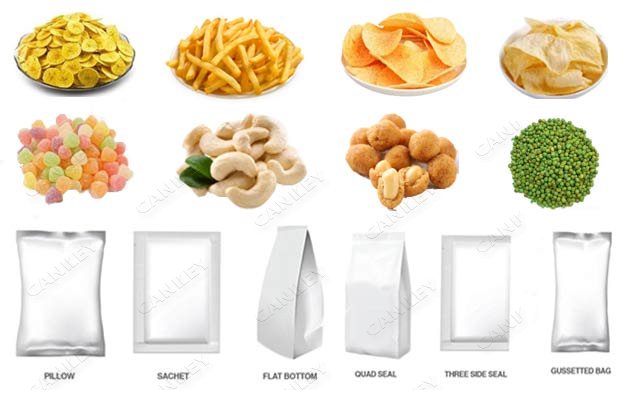

This plantain banana chips packing machine can be equipped with different weight and filling system for various granule, packaging such as peanuts, candies, cookies, potato chips, snacks,candy, pistachio, rice, sugar, beans, lentil, dried fruit, pet food,small hardware etc.

Working Processes :

Feeding--Conveying--Weighting--Forming ( Filling--Sealing ) --Finish Products Conveying

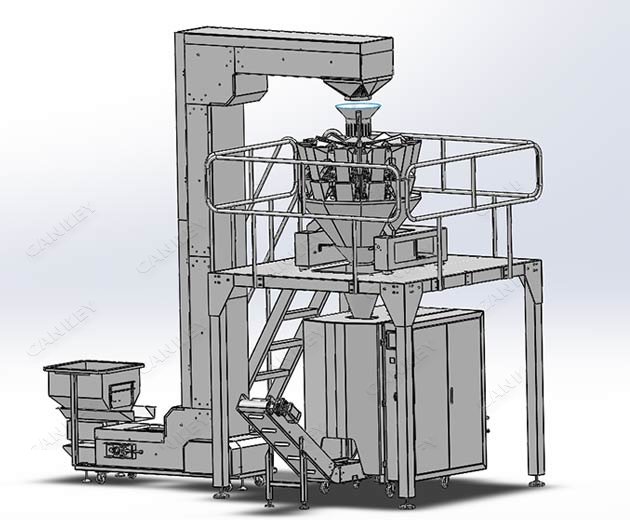

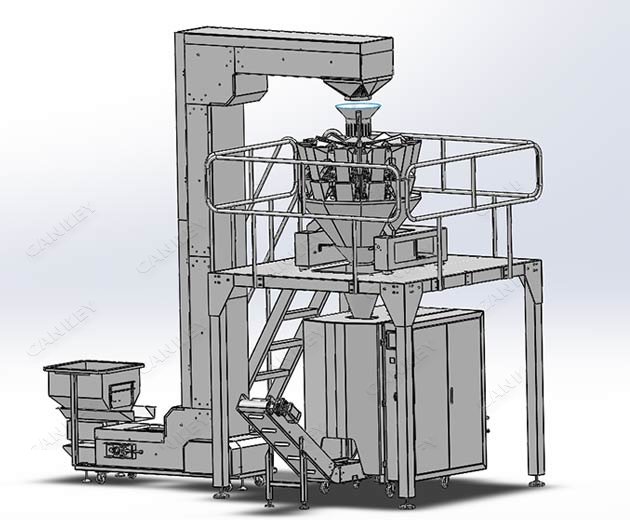

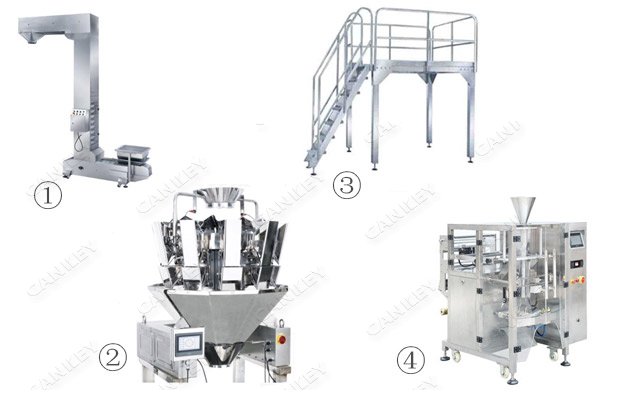

The total set of automatic plantain chips packing machine is consisted of:

Main Packing Machine: Digital screen display with numerical setting and flexible operation;Imported PLC control system and color touching screen, easy operation;PID independent control of temperature, more suitable for different packaging material

10 head combination weigher: suitable for weighing of granule, slice, roll or irregular shape materials such as candy, seed, jelly, fries, coffee granule, peanut, puffy food, biscuit, chocolate, nut, yogurt pet food, frozen foods, etc. It is also suitable for weighing small hardware and plastic component

Z type bucket chain elevator: Available for lifting of frangible and non-frangible material such as fried chips, prawn cracker, crispy rice, metals and medicines, etc.

Support Platform: Adopting support ten head weigher, easy to operation and watch the weigher runing .

Finish Product Conveyor: Adopting imported miniature motor and featured with low noise and long tifetime. It can transport finished goods to platform, reduce waste during packing, making the machine work more smoothly.

Technical characteristics of plantain chips filling packing machine:

★ English and Chinese screen display, it is simple to operate.

★ The function of PLC computer system is more stable, and it's more easy to adjust any parameters.

★ It can stock ten datas, and it's simple to change the parameters.

★ Sever motor drawing film, which is good to accurate location.

★ Independent temperature control system, the precision is accurate to ±1°C.

★ Horizontal, vertical temperature control, suitable for various of complex film, PE film packing material.

★ Packing type diversification, pillow sealing, standing type, punching etc.

Technical Data

| Model | CK-LK720 |

| Film width | max 720mm |

| Bag width | 110-350mm |

| Bag length | 100-420mm |

| Packing speed | 10-50bags/min |

| Packing range | 150-4000ml |

| Film thickness | 0.04-0.10mm |

| Power | 4kw/220v 50-60Hz |

| Machine size | 1780*1350*2000mm |

| Machine weight | 800kg |

| Air consumption | 0.8m³/min 0.8mpa |

Get Price

Get Price

E-Mail

E-Mail Whats

Whats TOP

TOP